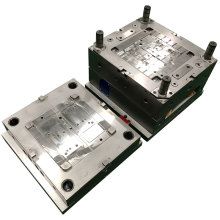

Plastic Injection Mould for Wheel Gear Mould

Basic Info

Model No.: TZRM-GM15017

Product Description

Model NO.: TZRM-GM15017 Surface Finish Process: Polishing Plastic Material: PP, PC, PS, PE, PU, PVC, ABS, PMMA Ect Application: Household Appliances, Commodity, Home Use Design Software: Ug, Proe, CAD, Cae, Cam, Caxa Ect Certification: SGS Customized: Customized Mould Material: 45#, 50#, P20, H13, 718, 2738, Nak80, S136, SKD61 Mould Design: 3D/2D Drawing Mould Life: 300, 000-3, 000, 000 Shots Payment: 40% of Deposit by T/T, 60% of Balance by T/T Trademark: REMO Origin: Taizhou China Shaping Mode: Injection Mould Mould Cavity: Single Cavity Process Combination Type: Progressive Die Runner: Hot/Cold Installation: Fixed Standard: as Requirement Name: Plastic Injection Mould for Wheel Gear Mould Base: Lkm, Hasco Ect. Design Days: 3 Days Injection System: Pin-Point-Gate Delivery Time: 15-60 Days Specification: International HS Code: 84807190 Plastic Injection Mould for Wheel Gear

1. High Quality Mould

2. Best Service Available

3. Mould Life:300, 000-3, 000, 000 shots

Remo is one of the most professional plastic mould manufacturers in China. We are specialized in opening new molds for various plastic products. We have the most advanced technology for wheel gear moulds and the most experienced workers for these moulds. Our mould quotation will be made in 1 day and sent to consumers for reference. Quantity of mould and delivery time will be guaranteed.

The following information will help you understand our molds better.

Products' information we need to make quotation Clear Pics/material/size/weight/wall thickness/targeting quantity and etc.

Mould Material 45#, 50#, P20, H13, 718, 2738, NAk80, S136, SKD61 etc

Mould Base LKM, HASCO ect.

Cavity Single/multi

Runner Hot/cold

Mould Design 3D/2D Drawing

Design Days 3 days

Design Software UG, PROE, CAD, CAE, CAM, CAXA ect

Plastic Material PP, PC, PS, PE, PU, PVC, ABS, PMMA ect

Mould Life 300, 000-3, 000, 000 shots

Injection System Pin-point-gate

Polish System Mirror Polish

Payment 40% of Deposit by T/T, 60% of Balance by T/T

Delivery Time 15-60 days

Specification depends on customers requirements.

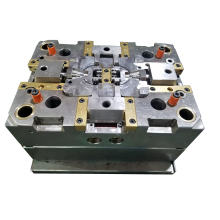

Our advantages:

1; Excellent Cooling System with extended cooling pipe

2; Copper Cooling for better cooling effects

3; Pre-opening system to improve cycle time

4; Semi-Hot Runner System to save clients cost on moulds

5; Mould Available for recycle Material

6; Excellent control of polish system

7; Weekly report with mould processing photos available

8; Samples and each trial out video available

9; Punctual sample time and delivery time

10; Logistic service available

11; Engineers available in client's factory for training

12; High quality mould with reasonable price

If you want to know more details, welcome to send an inquiry to us.

Contact us if you need more details on Plastic Wheel Gear Mould. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Wheel Gear Mold、Wheel Gear Mould. If these products fail to match your need, please contact us and we would like to provide relevant information.

1. High Quality Mould

2. Best Service Available

3. Mould Life:300, 000-3, 000, 000 shots

Remo is one of the most professional plastic mould manufacturers in China. We are specialized in opening new molds for various plastic products. We have the most advanced technology for wheel gear moulds and the most experienced workers for these moulds. Our mould quotation will be made in 1 day and sent to consumers for reference. Quantity of mould and delivery time will be guaranteed.

The following information will help you understand our molds better.

Products' information we need to make quotation Clear Pics/material/size/weight/wall thickness/targeting quantity and etc.

Mould Material 45#, 50#, P20, H13, 718, 2738, NAk80, S136, SKD61 etc

Mould Base LKM, HASCO ect.

Cavity Single/multi

Runner Hot/cold

Mould Design 3D/2D Drawing

Design Days 3 days

Design Software UG, PROE, CAD, CAE, CAM, CAXA ect

Plastic Material PP, PC, PS, PE, PU, PVC, ABS, PMMA ect

Mould Life 300, 000-3, 000, 000 shots

Injection System Pin-point-gate

Polish System Mirror Polish

Payment 40% of Deposit by T/T, 60% of Balance by T/T

Delivery Time 15-60 days

Specification depends on customers requirements.

| Business Steps | |

| 1. R& D | We support customers' R& D. We'll make the files or improve the design if you need |

| 2. Quotation Making | Mould Quotation will be finished in 1 day according to information we get. |

| 3. Negotiation | The quality, price, material, delivery time, payment item, ect. |

| 4. Mould Design | 3-5 days for mould and product 3D/2D drawing design |

| 5. Mould | We will build the mould based on customers' requirements. Before making the mould, we'll send mould design to customers' approval first. Mould will be usually finished in 25-60 days |

| 6. Mould Testing | When moulds are finished, we will test the moulds to check if it will satisfy consumers' needs. And we will send samples for consumers' reference. |

| 7. Sample shoot | If the first sample come out is not satisfied by customers, we will modify the mould until it can meet customers' needs. |

| 8. Delivery | Delivery goods by sea or by air, according to customers' requirements. |

Our advantages:

1; Excellent Cooling System with extended cooling pipe

2; Copper Cooling for better cooling effects

3; Pre-opening system to improve cycle time

4; Semi-Hot Runner System to save clients cost on moulds

5; Mould Available for recycle Material

6; Excellent control of polish system

7; Weekly report with mould processing photos available

8; Samples and each trial out video available

9; Punctual sample time and delivery time

10; Logistic service available

11; Engineers available in client's factory for training

12; High quality mould with reasonable price

If you want to know more details, welcome to send an inquiry to us.

Contact us if you need more details on Plastic Wheel Gear Mould. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Wheel Gear Mold、Wheel Gear Mould. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Commodity Mould

Other Products

Hot Products

Toy Car Plastic Part MouldFour-Way Connection Pipe Coupling MoldPlastic Cap Mould Injection Mold for PackageFast Cooling Plastic Injection Mould for Fan House Appliance (HQMOULD)Lego Block Mold/ Children Toy Part Injection MouldPlastic Injection 2-Side Pallet Mould for Logistic ProductDiffereent Models of Car Light Reflector Mould Injection Mould4 Cavity PVC Fitting Injection MoldPlastic Outdoor Chair Mould RemoPlastic Thin Wall Cup Injection Mould (RM0301078)Hot Sale PP Injection Bottle Crate MouldPlastic Car Battery Cover MouldPlastic Injection Moto Fitting MouldHigh Quality Plastic Injection Chair Mould / Furniture MoldPlastic Injection Dustbin Mould for OutdoorPlastic Injection Auto Parts Mould