Hq Plastic Footbath Injection Mould

Basic Info

Model No.: HQ-L233

Product Description

Model NO.: HQ-L233 Surface Finish Process: Polishing Plastic Material: PP Application: Commodity, Home Use Design Software: UG Certification: ISO Customized: Customized Cavity: Customized Delivery Time: 20-60days Specification: ISO9001: 2008 HS Code: 8480790090 Shaping Mode: Injection Mould Mould Cavity: Single Cavity Process Combination Type: Single-Process Mode Runner: Hot Runner Installation: Fixed Standard: DME Size: Customized Package: Wooden Box Trademark: HQ Mould Origin: Huangyan, China Product Description

China Plastic Injection Mould Manufacturer

"Making moulds, making art! " We always follow this principle, offer you competitive

price, high quality and good after services. Any of your inquiry will be highly appreciated!

We will reply you within 24 hours!

Main Products

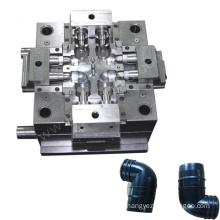

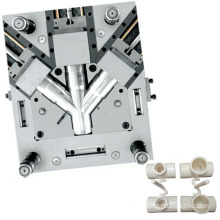

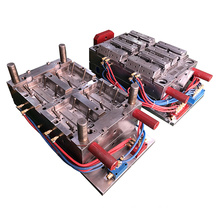

Business Scope: auto parts mold, moto parts mold, homeware parts mold,

logistic products mold, Pipe Fitting Mold, etc.

Above some samples' photos for your reference!

We also do customized mold for you!

Parameter Table

Our Service

1. with a year free service guarantee

2. We will send you final mold design drawings for you approval before making mold.

3. Any question, please feel free to contact us online or leave messages. We will get

back to you as soon as possible!

Business Procedure

FAQ

1.What's the delivery time?

30-45 days after the T/T deposit or L/C.

2.What's the payment?

T/T, 40% advance before mold designing, 30% after 1st try out sample delivering, 30%

before shipment.

L/C 100%

3.What's min order quantity?

1 set

Company Introduction

HQ Mould, founded in 1970, is a private company specialized in manufacturing plastic

injection mould. It is located in Taizhou Huangyan " Mould Town", a city with well

developed moulding industry, as well as good environment, transportation and

communication facilities. We have provided plastic moulds for home appliance,

automotive parts, pipe and fittings, etc.

HQ Mould occupies totally 12,000 square meters. We have more than 30 mould

manufacturing machines such as: 5 Axis CNC, high speed CNC, milling machine,

engraving machine, wire cutting machine, etc. With our advanced CAD/CAM, we

provide great service of " product development, mould design, mould manufacturing,

injection"

We now have 150 employees totally, including R&D engineers, tooling engineers, and

office workers. We were awarded ISO:9001 quality management system certification.

"Making Mould, Making Art", with high reputation our mould received worldwide

welcome. We are committed to become the world's top mould supplier based in China,

serving the world!

Why Choose Us?(Advantages)

1. We specialized in manufacturing plastic injection mould for over 40 years and

received a high evaluation and recognition of our customers .

2. We have a high-level designers team and we adopt advanced machine as

CNC\DMG\EDM\CMM.

3. During mold manufacturing, we keep customer updated with our ONLINE

TRACKING SYSTEM, which shows mold process clearly to customer from

Steel purchasing till Mold testing.

4. We have strict quality control system and have past ISO9001,2008 QC system.

5. We do not delay any project.

Contact Us

Tel:86-576-81107900

Mob:86-13456680008

Web:www.hqmould.com

Address:N0.818,Er Huan West Road,Huangyan,Taizhou,Zhejiang,China

Contact Us

Tel:86-576-81107901

Mob:86-18657658221

Web:www.hqmould.com

Address:N0.818,Er Huan West Road,Huangyan,Taizhou,Zhejiang,China

Contact us if you need more details on Footbath Mould. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Foot Washing Basin Mould、Food Basin. If these products fail to match your need, please contact us and we would like to provide relevant information.

China Plastic Injection Mould Manufacturer

"Making moulds, making art! " We always follow this principle, offer you competitive

price, high quality and good after services. Any of your inquiry will be highly appreciated!

We will reply you within 24 hours!

Main Products

Business Scope: auto parts mold, moto parts mold, homeware parts mold,

logistic products mold, Pipe Fitting Mold, etc.

Above some samples' photos for your reference!

We also do customized mold for you!

Parameter Table

| Main Technique Parameters | |

| Cavity/Core Material | 718H, P20, NAK80, 2316, S136, DIN1.2738, DIN1.2344, AISI H13 |

| Product Material | ABS, PC, PP, PVC, POM, PMMA, PS, PE, PET, Rubber, Silicone, PA, PBT, PEI, etc. |

| Base | LKM , DME, HASCO, etc. |

| Structure | 2 plate mold, 3 plate mold, core pulling mold |

| Runner System | Hot runner, Cold runner |

| Cavity | Single cavity, multi cavity by requested |

| Finish | Corrosion word, Mirror finish, Brushed |

| Longevity | 0.5-3 million shots |

| Mould standard | HASCO, DME, MISUMI, or by requested etc. |

| Software | CAD, Pro-E, UG, solid works, etc. |

| Tolerance | ± 0.02mm |

| Design Time | 3-7days |

| Sample time | 3-7days by express (DHL, TNT, etc.) |

| Main Technique | Milling, Grinding, EDM, Wire-cutting, Engraving, CNC, and 2.5 Dimension test, etc. |

| Manufacture time | 3-7 weeks, depends on mould structure |

| Packing | polywood case, or by request |

1. with a year free service guarantee

2. We will send you final mold design drawings for you approval before making mold.

3. Any question, please feel free to contact us online or leave messages. We will get

back to you as soon as possible!

Business Procedure

| 1. | Quoting Price based on customer's request. |

| 2. | Signing the sales contract/ Stamping Proforma Invoice. |

| 3. | Starting the 2D/3D drawing of the mould. |

| 4. | Sending customer mold 3D/2D design drawing for confirmation. |

| 5. | Starting Manufacturing after design approved by customer. |

| 6. | Testing mold with noticing customer. |

| 7. | Delivering the samples for customer's approval. |

| 8. | Doing final polish or treatment for the mold after samples approved. |

| 9. | Shipment. |

1.What's the delivery time?

30-45 days after the T/T deposit or L/C.

2.What's the payment?

T/T, 40% advance before mold designing, 30% after 1st try out sample delivering, 30%

before shipment.

L/C 100%

3.What's min order quantity?

1 set

Company Introduction

HQ Mould, founded in 1970, is a private company specialized in manufacturing plastic

injection mould. It is located in Taizhou Huangyan " Mould Town", a city with well

developed moulding industry, as well as good environment, transportation and

communication facilities. We have provided plastic moulds for home appliance,

automotive parts, pipe and fittings, etc.

HQ Mould occupies totally 12,000 square meters. We have more than 30 mould

manufacturing machines such as: 5 Axis CNC, high speed CNC, milling machine,

engraving machine, wire cutting machine, etc. With our advanced CAD/CAM, we

provide great service of " product development, mould design, mould manufacturing,

injection"

We now have 150 employees totally, including R&D engineers, tooling engineers, and

office workers. We were awarded ISO:9001 quality management system certification.

"Making Mould, Making Art", with high reputation our mould received worldwide

welcome. We are committed to become the world's top mould supplier based in China,

serving the world!

Why Choose Us?(Advantages)

1. We specialized in manufacturing plastic injection mould for over 40 years and

received a high evaluation and recognition of our customers .

2. We have a high-level designers team and we adopt advanced machine as

CNC\DMG\EDM\CMM.

3. During mold manufacturing, we keep customer updated with our ONLINE

TRACKING SYSTEM, which shows mold process clearly to customer from

Steel purchasing till Mold testing.

4. We have strict quality control system and have past ISO9001,2008 QC system.

5. We do not delay any project.

Contact Us

Tel:86-576-81107900

Mob:86-13456680008

Web:www.hqmould.com

Address:N0.818,Er Huan West Road,Huangyan,Taizhou,Zhejiang,China

Contact Us

Tel:86-576-81107901

Mob:86-18657658221

Web:www.hqmould.com

Address:N0.818,Er Huan West Road,Huangyan,Taizhou,Zhejiang,China

Contact us if you need more details on Footbath Mould. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Foot Washing Basin Mould、Food Basin. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Commodity Mould

Other Products

Hot Products

Toy Car Plastic Part MouldFour-Way Connection Pipe Coupling MoldPlastic Cap Mould Injection Mold for PackageFast Cooling Plastic Injection Mould for Fan House Appliance (HQMOULD)Lego Block Mold/ Children Toy Part Injection MouldPlastic Injection 2-Side Pallet Mould for Logistic ProductDiffereent Models of Car Light Reflector Mould Injection Mould4 Cavity PVC Fitting Injection MoldPlastic Outdoor Chair Mould RemoPlastic Thin Wall Cup Injection Mould (RM0301078)Hot Sale PP Injection Bottle Crate MouldPlastic Car Battery Cover MouldPlastic Injection Moto Fitting MouldHigh Quality Plastic Injection Chair Mould / Furniture MoldPlastic Injection Dustbin Mould for OutdoorPlastic Injection Auto Parts Mould